- NISIN was first discovered in the year 1928 and first isolated in the year 1947.

- NISIN was first used as food preservative in the year 1951. It was also recognized as ‘’food preservative’’ by FDA/FSSAI/DAO/WHO as a safe preservative and as a quickly digestible in human body, leaving no residue in the body.

- NISIN is applied as a food preservative inover 50 countries and areas all over the world. The products of Nisin enter into international markets, warmly welcomed by the consumers.

PROPERTIES :

- NISIN is a mixture of closely related antimicrobial polypepties, produced by strains of lactococcus lactis subsp. Lactis and can be digested into amino acids by a-chymotrypsin in human intestines and stomach.

- The use of NISIN will not affect the mornal bacterial community, nor produce the drug resisteance or chiasmatic resistance as it happened when the antibiotics used.

- NISIN is a non-poisonous and high efficacious food preservative/ anti-microbial agent.

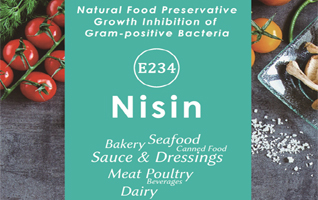

- NISIN possesses anti- microbial activity against a wide range of gran-positive bacteria, particularly those that produce spores, which are the major food spoilage organisms, such as clostridium botulinum. Staphylococcus aureus, streptococcus hemolyticus, listeria monocytogenes, bacillus stearothermophilus, bacillus subtilis etc.

ADVANTAGES :

- The use of NISIN as a food preservative, can

- Greatly decrease the required temperature

- Shorten the time in food hear processing,

- NISIN improves the nutritional value, appearance, flavor and texture fo foods, and significantly prolong the shelf-life.

- NISIN also saves the energy greatly and lower the product and production cost.

- Now, NISIN has been used in a wide range of processed foods, e.g. cured meat, dairy products, plant protein foods, canned foods, and heat treated/air-tightly packed foods etc.

- NISIN can also be used in the area of cosmetics, medicines and health products.

- NISIN can replace or partial replace chemical preservatives and meet consumer demand for food preserved with natural ingredients.

- NISIN is non-toxic; the producer strains of lactis are regarded as safe (food grade).

- NISIN is used alone or in combination with other preservatives e.g. benzoic acid, sorbic acid and potassium sorbate.

ANTI- MICROBIAL PROPERTIES :

NISIN possesses highly of inhibiting activites to gram- positive bacteria, particulary to spore-forming bacteria. It inhibits certain strains of the food pathogen, such as clostridium botulinum, staphylococcus aureus, streptococcus hemolyticus, listeria monocytogenes, bacillus stearothemophilus, bacillus subtilis and some others. It does not influence gram –negetive bacteria, yeasts and moulds generally, but under some circumstances (such as freezing, heating, low pph and adding of shigella spp, klebsiell spp Escherichia coli etc.

DOSAGE :

- The general dosage is 0.05gm / kg - 0.1gm /kg.

- The detail dosages of NISIN Depends on end products, raw materials quality, nature of the processes, shelf life of end products and storage conditions of end products etc.

Note : 1. Nisin can be dissolved in aqueous solution

2. NISIN is Insoluble in non-polar solvents.

3. The solubility decreases with increase of ph, and it increases with the rise the temp.

APPLICATIONS OF NISIN

NISIN as an effective natural food preservative can be used in a number of foods under the permission by local legislation. Some of the applications of NISIN are listed as follows.

1) Dairy products

2) Meat products and marine products

3) Coconut water

Dairy products :

a) Addition of 0.05gm/kg. NISIN to pasteurized milk, the storage period can be expanded over 2 times.

b) Adding 0.08gm. / kg to 0.1gm. / kg. NISIN to second disinfected milk and sterilizing at 115֯c for 15 minutes can make the products to reach the commercially ‘’no bacteria standard’’.

c) Usage of 0.05gm. /kg. NISIN in sour milk and fruit milk (about ph = 4) and sterilizing at 90 ֯c for 20 minutes can prolong the shelf life from 6 days up to over 1 month at ambient temperature.

d) Usage of 0.05gm. /kg. Nisin at UHT in bacteria – free packing milk, can reduce the rate of putrefaction from 0.04% to 0%.

e) Addition of 0.08gm. / kg. - 0.1gm. / kg. Nisin to no-sugar canned condensed milk can inhibit the out – growth of heat – resistant spores and decrease 10 minutes in heat process time.

f) Addition of 0.08gm. / kg. Nisin and treatment at 121֯c for 3 minu (i.e. fo = 3) can maintain the shelf life of low or non-fat milk, no – salt cream, and flavour milk to 6 weeks at 40֯c.

g) Addition of 0.05gm. /kg. to 0.01gm. / kg. Nisin to processing cheese can solve the putrefaction caused by gram-positive bacteria (such as clostridium botulinum and other anaerobic clostridium, lactobacillus bulgaricus etc.).

Important points to remember during application :-

1. Nisin can inhibit the gram-positive bacteria, but has no action on gram-negative bacteria, yeast and moulds. The usage of nisin combined with other food preservative will increase the effect when the products comtaminated gram-negative bacteria, yeasts and moulds.

2. The effects of nisin, as a food preservative is affected by the factors below :

a) The type of products: the contaminated microbes vary in products, and nisin possesses different inhibiting action on different microbes.

b) The degree of pollution and environment conditions: the deeper of pollution and the poorer of environment conditions, the more the nisin should be used, and the usage of Nisin will not be effective for the rotten products.

c) The ph of products: nisin is effective with a wide range of ph level (3.5 - - 8.0). it is stable at low ph value.

d) The moisture, fat and salt in the products: the products with high moisture, high fat and low salts will need more usage of Nisin.

e) The types of flavour additives: the mixture of oxidizing flavour additives can decrease the effect the nisin.

f) The process and the package materials: the appropriate process and the cleaned package materials will optimize effects for the usage of Nisin.

g) The homogeneous degree of the mixture of the product and Nisin: the parts of the product without touch with Nisin are not effective.

h) The amount of Nisin used varies with storage temperature and the shelf life.

-

News

Company Profile

2017-09-29

EXHIBITIONS GALLERY

2017-09-29

WHY SYNTHETIC PRESERVATIVE IS NOT GOOD?

2017-09-29